Megafood Factory Tour

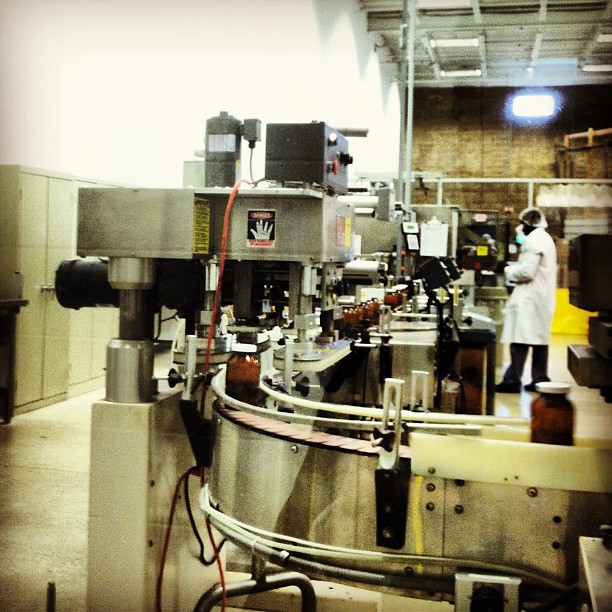

Recently some staff members from the HL VT Wellness Department took a trip to the Megafood headquarters in Londonderry, NH to tour the factory and learn more about their unique process for producing whole-food supplements.

Megafood partnered with researchers at the University of New Hampshire to develop the unique Slo-Food Process™ which is used to make the MegaFood products.

This slower, gentler way of making whole food supplements was designed to optimize the potency of the vitamins or minerals found within the whole foods selected to create their FoodState Nutrients™.

The process of creating these FoodState Nutrients™ begins with the raw materials. Megafood sources food from farms as close to home as possible, and they are delivered fresh frozen to the doorstep of their manufacturing facility in Londonderry, New Hampshire.

After testing each of the raw materials for potency & to ensure that they are free of allergens, they use a cold-milling process to break down indigestible plant fibers and enhance digestibility, natural enzymatic pre-digestion to improve bioavailability and gentle drying to maximize nutrient retention.

Heat-free tableting and glass bottles ensure that the foods are as nutrient rich when they reach each customer as they were when they were delivered in their fresh, raw form.

Made with love in New Hampshire since 1973, Megafood has been dedicated to providing you the best in whole food supplements for almost 40 years!