Featured Cheese of the Week: Orb Weaver

3/26/2012

When farmers use milk exclusively from their own cows to make cheese, it’s called “farmhouse cheese.” That’s what Marjorie Susman and Marian Pollack of New Haven, Vermont have been doing at their ‘Orb Weaver’ farm since 1982. The raw milk used to make this cheese comes from happy Jersey cows. The Jersey milk helps in making a rich cheese with a slightly tangy and full bodied flavor. More moist than a cheddar, the Farmhouse Cheese has a natural buttery color and smooth, creamy texture. The cave aged cheese has an amazing sharp flavor. The cheeses are produced simply and in the European tradition. They stir, form, and date-stamp each wheel by hand–not using mechanical stirrers or hydraulic presses. The wheels are then age for a few months and, since the ladies do everything their selves, quantities are limited. They make cheese from November through May. The cows are given a break every summer to graze the beautiful Vermont countryside while the ladies tend to their amazing organic gardens while practicing sustainable farming. This cheese is delicious right off the wheel with a glass of wine, melts beautifully to complement any recipe, brings grilled cheese sandwiches to new heights, and distinctively tops nachos and pizza. Our cheese department staff was lucky to go to visit Orb weaver a few weeks ago and make cheese. Here is the story of our visit:

It’s 10:00am and we’re in the small, warm, milky-smelling cheesemaking room at Orb Weaver Farm, located in New Haven,Vermont. Marjorie Susman, who owns and runs the farm together with partner Marian Pollack (currently out doing what is affectionately and vaguely called “cow stuff”), greets us warmly and invites our observation as she fills us in on what we’ve missed so far. Inside the vat is what appears to simply be rich Jersey milk, but it is in fact already well on its way to being cheese; the starter culture and rennet have already been added to the milk which was pumped in from the bulk tank as well as the morning’s milking (aha: “cow stuff”!) The only thing missing from the vat is the gallon of cream which Marjorie skimmed off, destined to be transformed into homemade cultured butter tonight!

While we wait for the rennet to work its magic (rennet is what’s ultimately responsible for coagulating the milk and separating the curds from whey), Marjorie shows us the aging room where there are but seven racks laden with their recognizable yellow waxed wheels of farmhouse cheese. We’re surprised to hear that of the seven, only two are holding wheels which are ready to sell. Knowing how popular their cheeses are at our own store, it’s amazing to hear that these women have chosen to only work with a small but devoted number of customers, including ourselves, and this makes us feel both lucky and honored. The rack closest to us is filled with wax-less wheels: these were made just last week and are in the process of creating the tiniest of rinds before being waxed.

Back in the cheese room, Marjorie tells us of their early days in the cheese making business, and what it was like to be the first commercial farmstead cheesemakers in Vermont. When they began, after taking only one class with Ricky Carroll, they had to learn everything from scratch and developed their recipe, methods, and techniques purely through trial and error. They were so far ahead of the curve, there weren’t even any cheese inspectors for farmstead cheesemakers around! While painting this picture for us, we who only know Vermont filled with farmstead and artisan cheese, she releases the water from the water bath surrounding the vat, meaning it’s time to cut the curds. Marjorie pokes a finger into the solid substance and lifts a bit to find what is called the “clean cut” and then employs two harps, horizontal and vertical, to detach the curds from the whey. She’s asked what size curds she’s looking to create and, although responding politely by indicating the space between the tines, she also gives a look that says “You clearly don’t know how we work here.” And it’s instantly apparent that the question is simply too precise for this operation, which is more art than science. It seems like she still loves making cheese and she’s asked if it is still satisfying. She responds that it is, adding, “What else are you going to do in the winter?”

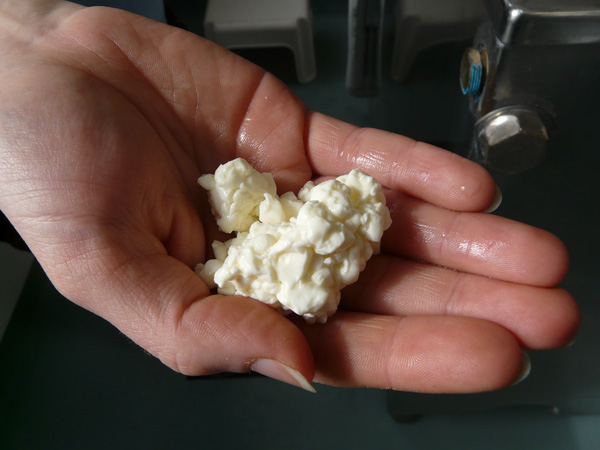

For the next hour or so, the curds are left to rest and heat up slowly and then there is a considerable amount of stirring. That’s an understatement: there is a lot of stirring, which might at times become somewhat tedious for our cheesemaking friend, but it gives us a chance to discuss things like types of rennet (Marjorie and Marian use calf rennet, known for its purity), the ancient the art of cheesemaking, the beauty of their Kodova plastic molds and cheese cloths (how strange and lovely that plastic cheese cloths can sincerely be considered “beautiful”), their raw milk sales ($8 per gallon available at their farm only), and the variety of cheeses they enjoy. This leads to a conversation about how wonderful it is when small Vermont cheesemakers know, try, and even buy each other’s products. It doesn’t always happen, even here in Vermont, but it feels like a big supportive community when it does. Much to our joy, we are treated to three curd tastings throughout this time and it’s a delight to see their character transition from something Marjorie describes as “the essence of milk” to tiny nuggets of firm but supple pre-farmhouse cheese goodness.

Marian comes in after doing “cow stuff” and works seamlessly around Marjorie, making it clear what a well-oiled operation this is. There’s a rhythm that is part science, lots of experience, and evident joy. It seems the two women don’t even need to converse; there is only one instance of direct communication, when Marjorie says simply, “four minutes” and Marian knows precisely what that means. While Marjorie continues stirring, Marian sets out the stamps for the cave-aged wheels: today, batch #24, two big and two small cave-aged wheels are being made.

It’s 11:30am and the whey is finally being drained. For twenty minutes, the women work the curd loose. The room is filled with a vanilla ice cream smell and Marjorie and Marian are bent over double, working together, sharing this experience as they do every winter, heads together, hands in the curds. They seem younger and you can see the “figure it out on our own” mentality at play here. Marian says, “Everything we do is designed for two people”, a fact which Marjorie explains helps the enviable consistency of their makes. They never have a failed batch not only because the seasonality, milk quality, and feed safety are always consistent; the batches are also always successful because with just two people involved, doing exactly the same process each time without any shortcuts taken, everything remains the same, and consistency is a given.

Before the curds are weighed out into their molds, 3.5 pounds of salt are added and we do a before-and-after taste to see how the salt brings out the sweetness. We love the taste of the curds already, but with the salt? WOW! They have a buttered popcorn flavor that is irresistible. When molding time comes, the two-person team is back in action; Marian takes the two-pound wheels and Marjorie the six-pound ones as well as the cave-aged wheels. Each mold is weighed, topped with a cheesecloth and lid, and flipped. Marjorie periodically hands us more curds and we’re eager to eat them up! She and Marian also sneak some tastes themselves; partly for quality control I’m sure, but more likely for the pure joy of trying their hand-crafted cheese straight out of the vat.

It’s 12:15pm and while Marjorie begins cleaning the vat, Marian is flipping the molds and applying pressure with a Dutch apparatus that uses two things: leverage and jugs of water. That’s it. Right now, just one jug is attached; another will be added in about an hour, and the third and final jug will be added later in the afternoon. With that, the make is done!

And while it might seem like what was made were only twelve six-pound, two ten-pound, and eleven two-pound wheels of delicious cheese, it’s also true that this experience made us truly realize what a remarkable operation this is. We were struck by the idea that this is a place where everything is “just right.” It’s more craft than science, it’s consistent but not exact, it’s satisfying and successful, and it’s a labor of love custom-built by two for two. And we really appreciated you sharing it with us, ladies. Thank you!